SOLUTIONS FOR THE FABLESS INDUSTRY

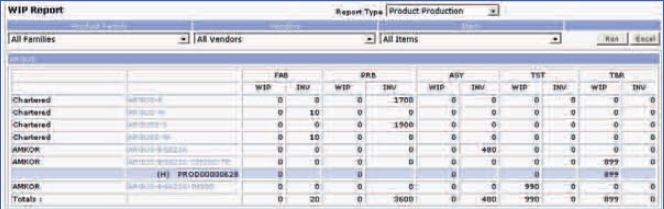

Complete WIP and inventory management support for semiconductor operations, including yield and cycle time history, consolidated WIP status, complete forward and backward product genealogy, complete lot and product attribute tracking, all fully integrated with planning, customer service, and ERP.

Benefits

Streamlines Business Processes

Lot routing, procurement, and inventory valuation are integrated into one transaction flow, eliminating unneeded steps and streamlining the overall outsourced manufacturing process.

Supports Semiconductor Manufacturing

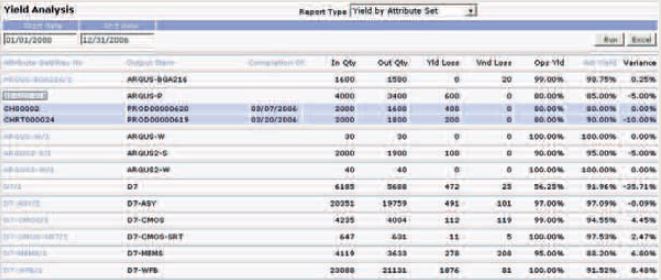

Production models are based on an inverted BOM and many to one production model. Multiple production models, yield and cycle time requirements, binning and multiple package options, as well as downgrades and rework, are all fully supported.

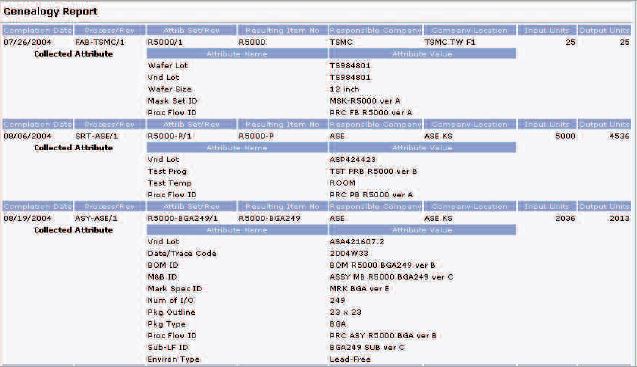

Delivers Full Lot Genealogy

Wafer lot, internal lot, and vendor lot can be tracked for every step in the process. Unlimited production attributes can be tracked and used for detailed analysis. Every part has full genealogy associated with it at all times.

Features Overview:

Operation Cycle Time Management

Ability to track cycle time data by product, vendor, production step, and product variables for detailed sorting and analysis.

Streamlined Processes

Integrated procurement, production, and lot routing business processes, to streamline management of outsourced production.

Operations Yield Management

Ability to track yield data by product, vendor, production step, and product variables, for detailed sorting and analysis.

Vendor Integration

Automated updates from vendors and contract manufacturers to status WIP and inventory, and for real-time analysis of vendor data. Enables improved data quality and supports on-time delivery.

Lot Routing (Split/Merges, Genealogy)

Track wafer lot, vendor lot, and internal lot at every step of the production process. Maintain and track complete lot history, product identification and process genealogy, for forward and backward tracking. Fully supports lot splits and merges.

Semiconductor Production Model

Support for multiple units of measure including input, output, and procurement. Built around the concept of the inverted bill of materials. Support for genealogy, and multiple packaging options.

Multi-Chip Module

Support for multiple die in one package. Includes indented genealogy and consigned material consumption management for tracking substrate lots or other production materials.

Re-work, Re-Screen, Re-Test

Supports test analysis and production enhancement, reclamation and bonus processes, as well as re-test and re-screen production processes. Captures detailed scrap and yield information, quarantine material, and variances.

Fully Auditable

Tracks and saves a complete process history of every vendor and production step, including detailed product and production information by step.

Easy Integration

Full integration with planning and forecasting modules. Flexible integration options for integration success, providing benefits such as a closed loop process for 3-way match of order to approved production completion, to vendor invoice, and production pay-points fully integrated with payables process.