SOLUTIONS FOR FABLESS INDUSTRY

Quickly and accurately plan for material requirements with Tensoft SemiOps Planning and Forecasting. Improve your business performance and exploit supply chain opportunities with unified strategic, tactical and operational supply chain optimization, with visibility to all stakeholders.

Increase Delivery Date Accuracy

Reduce your incidence of missed ship dates with automatic commit date updates to customer service.

Cut Planning Lead Times

Global view of supply and demand facilitates smarter, faster decision-making.

Reduce Inventory Exposure

Manage die banks and inventories more precisely and improve cost efficiencies up and down the supply chain, increasing inventory turns.

Stay Continuously Informed

Quickly answer business-critical questions about resource availability.

Decrease Manufacturing Cycle Times

With global views of supply, capacity can be allocated more responsively.

Increase Planning Accuracy

Create more reliable long-term projections and respond faster to short-term fluctuations.

Stabilize and Optimize Inventories

Moderate short-term demand fluctuations, reducing WIP inventories and minimizing obsolete stocks.

Features Overview

Semiconductor Manufacturing

Supports inverted BOM one-to-many production model, distributed supply chain (COTS), multi-vendor production sourcing, multiple end products from one wafer, wafer-to-die conversion, programmable devices, multi-chip modules, re-marking and re-screening, yields and cycle times by production step, binning and downgrading.

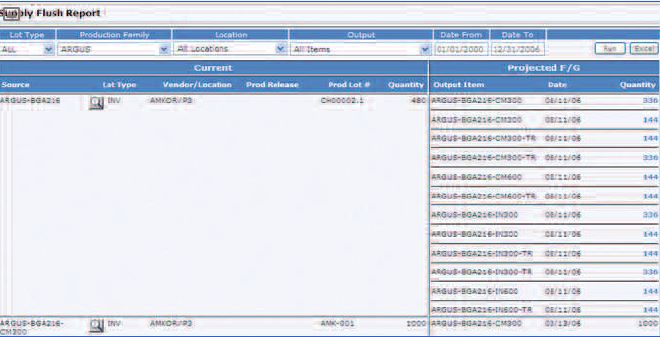

Supply Management

Full supply flush to all potential finished goods items makes efficient use of existing material. If supply is short after demand match, starts are recommended based on standard yield and cycle time requirements.

Supply/Demand Match

Demand includes backlog, forecast, and component material (for multi-chip modules, substrates, etc.). Forecast is netted. Planners view suggested supply routes to meet demand, and make specific routing decisions as required. Demand priority and supply priority are considered in the match.

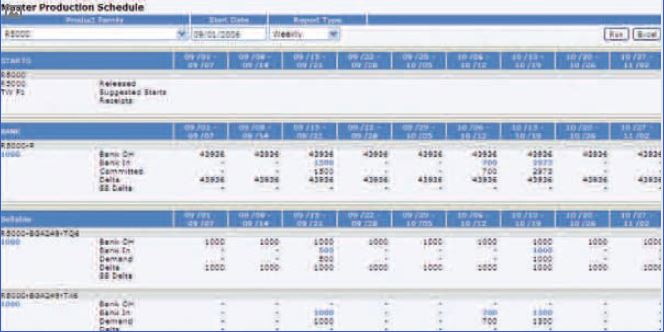

Production Planning and Vendor Forecasting

Planned production orders and starts generate forecasted vendor orders and inventory. Vendor production forecast meets requirements for vendor partnerships and capacity planning.

Multi-level Demand Forecasting

Easily upload and download forecasts; unlimited versions stored by “as of” date and version. Store history for trend and accuracy analysis, waterfall view and performance graphs. Supply demand match nets at the product or customer level by period.

Planner Tools

Ability to hard peg or soft peg supply demand match. Time fence capability to support planner-defined or managed events. Safety stock by part and location for saleable items as well as bank items. Production calculator automates computations for timelines and required quantities. Exception management for lates, shorts, vendor/plan mismatch, pegging yield shortage, as well as user-defined exception handling.

Planner’s Dashboard

Task list highlights required starts and planned production orders with insight into end demand fulfilled. Fully streamlined integration into procurement and lot routing. Ability to link in exception reporting for actionable events.

Real-time Available-to-Promise (ATP)

Planner actions update customer service’s visibility into available material including override/issue messages. ATP includes planned and actual supply, backlog and forecast demand. Customer service can take customer calls and provide immediate response.

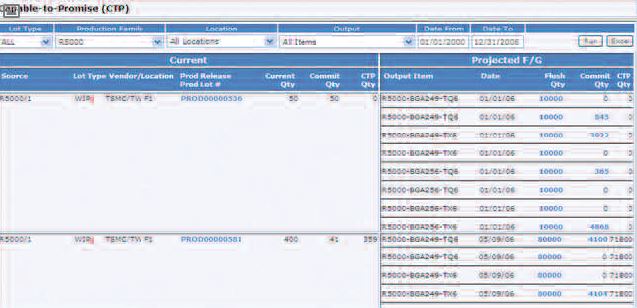

Real-time Capable-to-Promise (CTP)

Planners can view the potential to deliver unplanned orders based on existing supply, which is unmatched to demand. Quick visibility supports fast response times and the ability to accept additional demand when possible.

Calculate and Report Excess Inventory

Including actual or projected inventory over demand forecast.

Automated Interface to Subcontractors

Integration mapping server allows planners to easily import detailed WIP data from vendors.

Full Integration with ERP

Fully integrated with production and inventory modules as well as forecast.