SAAS SOLUTIONS FOR THE FABLESS INDUSTRY

Supplier Integrations-as-a-Service

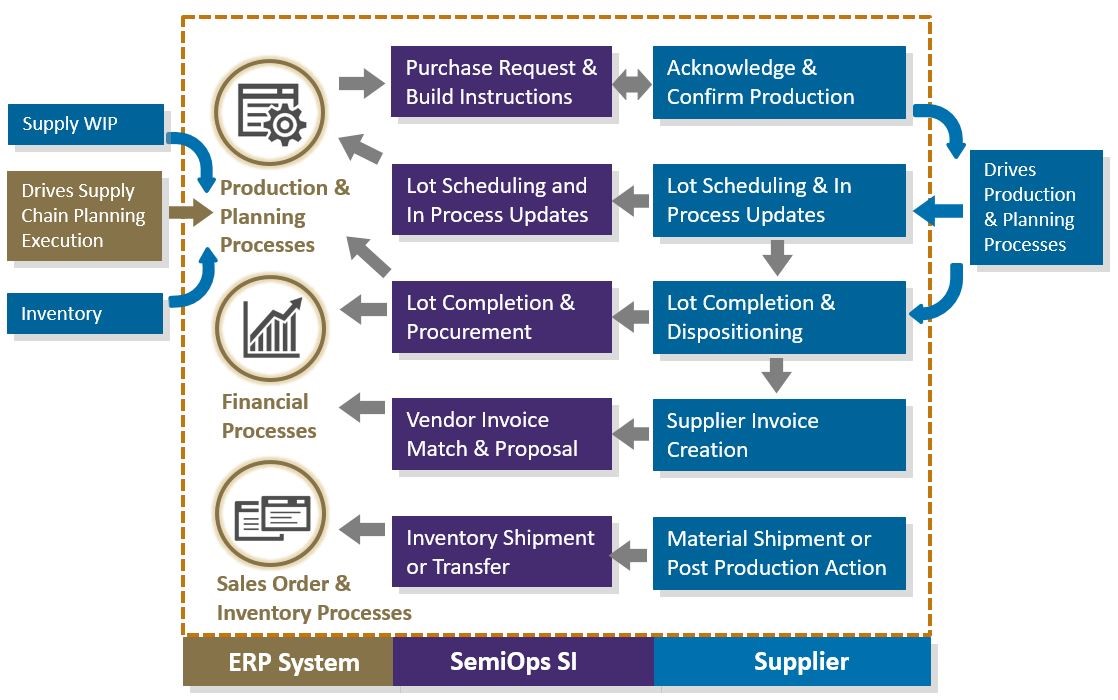

Simplify the typical integration challenges across the fabless semiconductor supply chain by automating communications with suppliers, and gaining visibility into real-time production activity. With Tensoft SemiOps SI, you can easily and more accurately track product progress from wafer fabrication, through OSAT production, to delivery. Successfully connected with most first-tier subcontractors and many second-tier subcontractors, Tensoft’s proven cloud-based solution ensures integration to smaller suppliers as well as internal production stages and systems.

Tensoft SemiOps SI synchronizes operations and production finance transactions through collaborative information exchange at every major stage of production. Delivered as a highly secure, turnkey subscription service, SemiOps SI additionally includes an enterprise grade integration platform with prebuilt connectors to major ERP systems for automated data population.

Increase Velocity

Speed information flow to all relevant parties, including internal clients, partners and customers.

Improve Efficiency

Communicate effectively with all suppliers at all phases of the process. Automate time-consuming transactions, eliminate error correction.

Broaden Visibility

Gain access and insight into detailed levels of supplier data and history

to improve planning, transparency and oversight.

Better Data Accuracy

Easily detect and correct errors or discrepancies in vendor data before it goes into the ERP system.

Reduce Costs

Efficient and accurate data collection helps reduce costs by saving time and conserving valuable resources.

Measure Supplier Performance

Real-time communication, requested execution validation, and continual synchronization and comparison provide data to measure supplier performance and help ensure accountability.

Features Overview:

Live Integrations with Top-Tier Suppliers

Successfully connected to most first-tier suppliers and many second-tier suppliers. Flexible, proven methodology for adding suppliers allows integration via the most optimal method in each circumstance.

Production Orders and Forecast Information

Communicates outbound forecasted and actual production requests to the supplier and returning inbound production order acknowledgements.

WIP Options

Collects real-time updates on supplier material moves, released lots, expected outdates, and on-time delivery status. Complete history maintained for traceability.

Shipment Options

Collects production completion data to record lot movement, actual cycle times and yields, production genealogy information, and confirmed production receipts. Pay-point completion steps queued for production control acceptance and the integrated production payables process. Lot clarity and procurement requirement rules enforced.

Industry Specific Integration to Supplier and Internal Systems

Flexible options for Tensoft’s fully managed integration service. Multiple connectivity models available, depending on supplier systems and capabilities. B2B integration models vary depending on subcontractor’s technological requirements spanning spreadsheet or flat files to sophisticated RosettaNet transactions. Connects internal shop floor systems too.

Supplier Data Integrity Monitoring

Move hard data evaluations with suppliers by maintaining a complete history of on-time delivery, supplier data quality and supplier performance. Identify exceptions and mismatches in supplier systems through comparisons to internal production control data.

Data Cleansing

Built-in processes for data cleansing and upload validation provide for clean data through an always-running and always-available system. Allows customers to check for discrepancies and fix errors before acceptance.

Self-Service Analysis & Reporting

Access to both raw data and robust analytical tools to sort, query and intelligently interpret critical data and key trends across the supply chain spectrum. Powerful dashboard options available including Microsoft Power BI.