We often get asked, “what is the difference between production planning and production control in SemiOps” or “what is production control” occasionally.

We often get asked, “what is the difference between production planning and production control in SemiOps” or “what is production control” occasionally.

The distinction is important to look at how your team matches up to the system functional blocks and to help think through all of the required business processes that are required for Semi Operations.

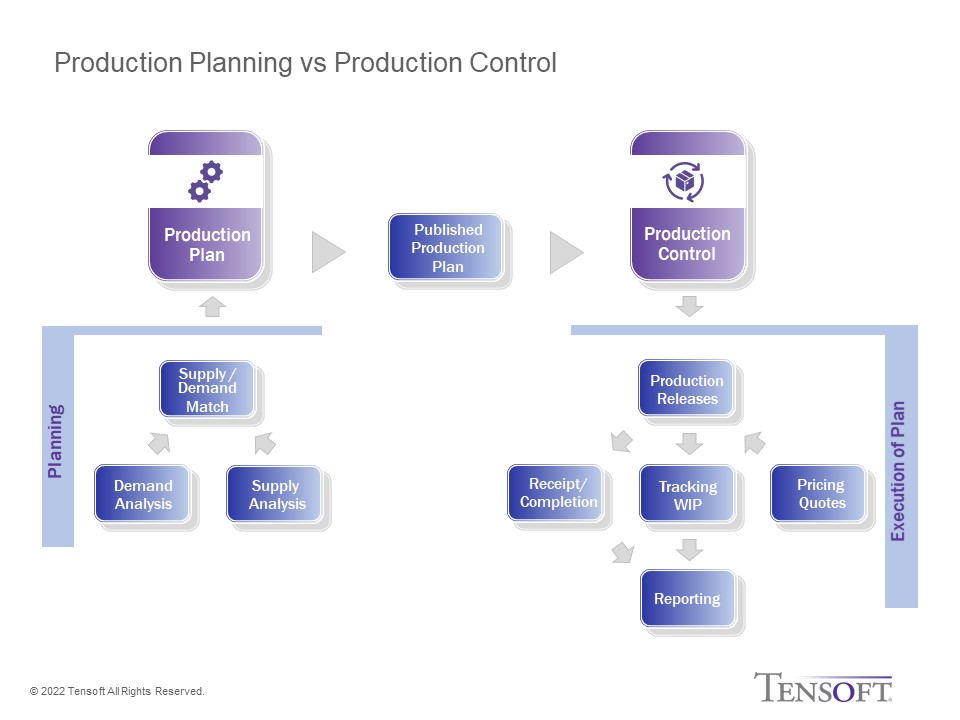

Production Planning, using the SemiOps planning module, analyzes supply and demand to recommend a production plan. The production plan supports recommendations for production orders to suppliers and for backlog commit dates. It supports reporting and thinking about how the company will meet production objectives and deliver products to customers. It is understanding both available supply and future supply, understanding demand and what needs to be done and when. This is the point where production control picks up.

Production Control is about executing the plan. It is the process of managing the day-to-day moves and transactions with suppliers. Suppliers have procurement processes and may require build instructions, likely using a quote from the supplier you have previously negotiated. Once production starts the suppliers will update you on the status of delivery, will ask you to acknowledge completion of production steps, and support moves to continue the production process. Reporting of ‘what is’ rather than ‘what could be’ is core to Production Control.

Planning is looking ahead and saying what should be, whereas production control is the processes of ordering, receiving, acknowledging the transaction flow with suppliers. The Operational leadership and strategists think more on the planning part and not on the execution. In order to make things work you really need to have the execution part done well too. Both planning and production control are equally important for success.

To get a high-level overview of how production planning works in Tensoft SemiOps, read this blog post. For more information on Tensoft SemiOps and its features, click here or contact us!