In Part 2 of our series based on the article titled “Anatomy of a Successful Supply Chain Integration” which was written for the Global Semiconductor Alliance’s Forum, we’ll be looking at supply chain integration from the perspective of a semiconductor subcontractors, Trisha Giacopazzi from Amkor Technology, Inc. All three parts from this series were excerpted from GSA Forum’s article.

Question: What are your goals for the integration?

Answer: It is very helpful to identify and involve all stakeholders who will be directly or indirectly impacted by the B2B integration project. For this integration, the list included the assembly and test provider’s IT, factory, finance and sales teams; the semiconductor company’s planning, operations and finance teams and the SCM provider’s technical project team. This let us train stakeholders on how the B2B integration works: What are the key triggers? What is the critical data for reporting? How is the data being applied in the customer system? Once stakeholders are trained, they will understand how a change in process (manufacturing or billing) can impact the B2B integration and notify others of changes. Additionally, we are looking to develop test plans and scenarios that will validate that all requirements have been met during User Acceptance Testing (UAT).

Question: What tips do you have for effective partnering?

Answer: Any new business processes or data input requirements should be addressed ahead of the B2B integration project (i.e. change in customer part numbers to be reported or a new service being introduced) since this type of effort can be time-consuming and negatively impact the B2B project schedule. If such changes cannot be made ahead of the B2B integration project, then these activities should be planned for in the B2B Integration project plan.

Here are basic tasks that assembly and test provider should follow:

- Receive request from the fabless semiconductor company and start the process to initiate the project, identify all stakeholders and obtain necessary approvals.

- Perform analysis to identify assembly and test provider sites and billable services being performed to select the standard WIP transactions that aligns with customer-specific bill trigger/pay points.

- Configure and test B2B reporting (unit test, integration test, connectivity) and promote to quality assurance (QA) environment.

- Deliver data to assembly and test provider’s FTP service via a secured customer account for pick and processing by the SCM provider.

- SCM provider transform data into the SCM provider system and work with the customer to support UAT.

- Upon UAT approval, deploy to production.

- Perform post-deploy validation and customer satisfaction survey.

Outsourced production processes require seamless collaboration– no one knows this better than the semiconductor companies and their suppliers. As you’ve read above and in the first part of the three-part series, all parties in the supply chain benefit when each company communicates needs and wants effectively. For more tips and perspectives, read Part I

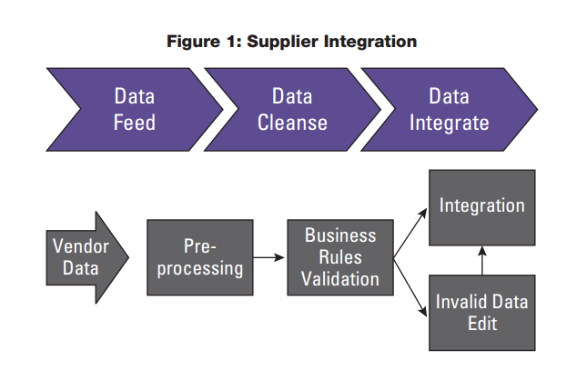

The Tensoft SemiOps SI (Supplier Integration) application automates communication between your subcontractor, supply chain vendors and Tensoft SemiOps, providing real-time visibility into your production activity. For more information about this service, please contact us.