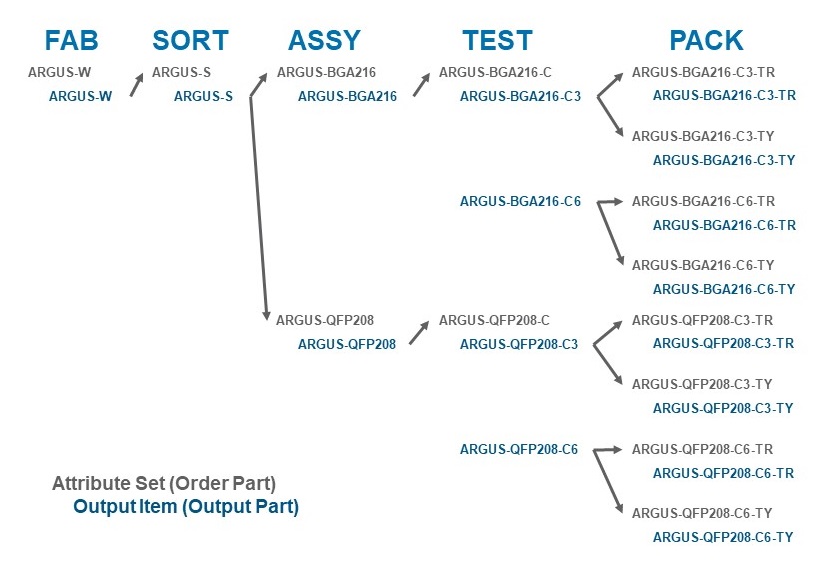

We define supply chain as component sourcing from multiple suppliers brought together to build a product. For semiconductor companies, there are some components, but it is mostly about the process. The semiconductor supply chain is a series of process steps–often done at multiple locations and with multiple suppliers. Instead of procuring materials to build one product, a particular part like a wafer is probed or run through a die saw, or a PCB is put through different tests and moved on to the next process.

We define supply chain as component sourcing from multiple suppliers brought together to build a product. For semiconductor companies, there are some components, but it is mostly about the process. The semiconductor supply chain is a series of process steps–often done at multiple locations and with multiple suppliers. Instead of procuring materials to build one product, a particular part like a wafer is probed or run through a die saw, or a PCB is put through different tests and moved on to the next process.

While one of the significant revolutions in semiconductor manufacturing has been the growth of external suppliers and the growth of the fabless model, some companies do have one or more processing steps internally. This may be an early growth model or a ‘secret sauce’ type manufacturing process, or for whatever practical or strategic reason exists. The system needs for managing an internal production step are different than the types of systems needed for a supply chain overall. Internal production areas may need simple systems support (manual router) or sophisticated systems support (like an MES, or manufacturing execution system).

From a supply chain perspective, Tensoft SemiOps links process steps across locations. The locations can be internal or external–it doesn’t really matter. It can link internal and external production points into a single supply chain model to give you the overall business production, planning, distribution, and finance tool needed for managing your semiconductor production.

In Tensoft SemiOps, processes are templates that users can create which allow you to select a vendor and a set of attributes or data types you can collect in the template. For example, an OSAT process might be named TEST-AMKOR and used as a template to test certain parts in a production process.

Once parts (attribute sets) are created from these process templates, they can be linked together to form an inverted bill of materials (IBOM) to represent the range of possible steps to create a finished good.

If the series of processes requires an internal production step, Tensoft SemiOps can specify this when creating the process template by selecting the vendor as the internal company utilizing SemiOps. When receiving these parts through an internal production flow, it would usually go through as a 0 dollar PO to the internal company, and the output part would change as work is completed to the part internally.

To learn more about Tensoft SemiOps and its capabilities, view this factsheet. For a quick demo of SemiOps, contact us today!