Usually in semiconductor production process, we use an inverted bill of materials (IBOM). A wafer in the inverted bill of materials can become multiple different finished goods instead of multiple parts in a bill of materials all coming together to be built into a finished good.

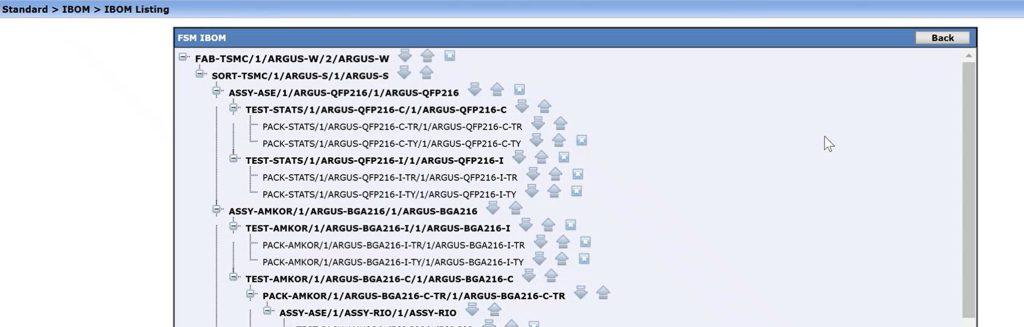

The screenshot below shows the inverted bill of materials for one of the wafers in Tensoft SemiOps. The starting item is Argus-W wafer and as it goes through the production process, it can go through different paths, different vendors, different assembly processes and then each of those processes can go to different testing paths and different ways to pack after the testing is completed. There are different ranges of options this one item can become.

For this process, it is required that the output of one step becomes the input to the next step in a one-to-one relationship. So, whatever comes out of the probe or the sorting step, and when you get the die, that die then becomes the input for the next assembly step and the output from that step becomes the input to the next step for testing.

Sometimes, processes need more than a traditional inverted bill of material structure. Instead of a one-to-one relationship, you may require more than one item to become the input for the next item. This is where the Consumed Material model is helpful.

An example of that could be the Assembly step. When the die is sorted or probed, sometimes the assembly will require additional substrates or additional components for the assembly process to finish and output that good. In SemiOps, you can set it up and consume as many materials as you need and at the quantity that is necessary. If it is a two to one relationship, for every one assembly part, you will need to consume two quantities of a substrate. On top of additional substrate materials for an assembly process, you could also use this model for a module or a kit.

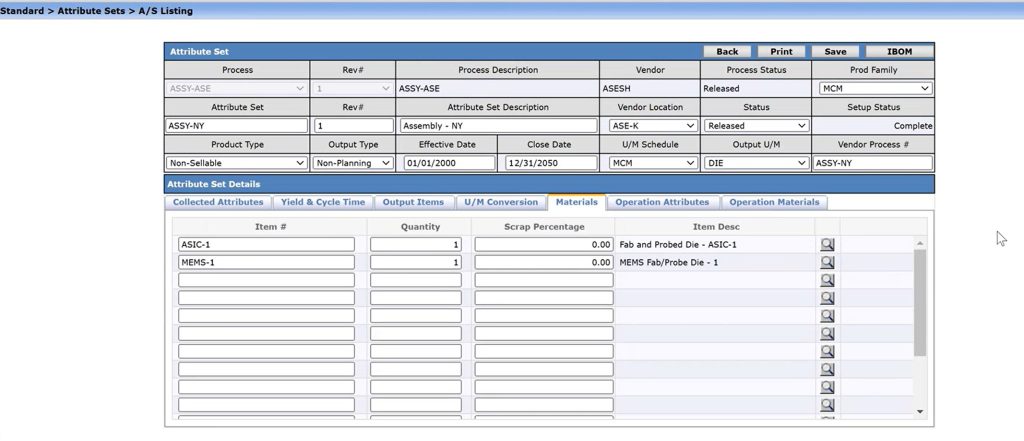

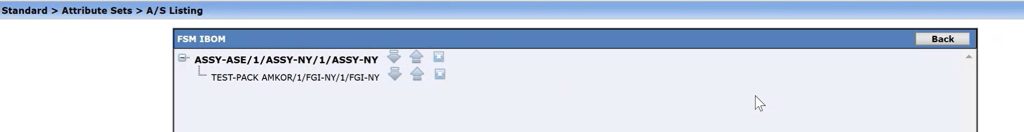

If you want to follow more of a traditional bill of material structure, you can have that as the beginning process. In the screenshot below, you can see that this ASSY part requires an ASIC and MEMS item. Both are probe die but if you check the IBOM for this part, this is the beginning process in the bill of materials. There is no input from an IBOM, it is only the input from the consumed materials. This is more of a traditional bill of material set up in which you have many materials coming together to build one item. You can continue further and test that output part and it can become multiple things and follow more of an IBOM approach.

The receipts and the PR are a little different for this model. If there are consumed parts, you will need to allocate those materials into the PR. There are also standard costing considerations that you need to consider, and the standard cost needs to be reflected in the inventory. The cost of the part that consumes components will need to increase its cost accordingly.

To learn more about Tensoft SemiOps and how it can help your business, please contact us today.