Many semiconductor operations rely on spreadsheets to track wafers, WIP, receipts, and invoices. While spreadsheets may feel familiar, they hide major operational costs especially when compared to automated integrations. Most teams don’t notice these costs at first simply because they’ve never experienced a fully streamlined alternative.

Many semiconductor operations rely on spreadsheets to track wafers, WIP, receipts, and invoices. While spreadsheets may feel familiar, they hide major operational costs especially when compared to automated integrations. Most teams don’t notice these costs at first simply because they’ve never experienced a fully streamlined alternative.

But once manufacturers see what an integrated process looks like, the benefits become obvious. We have seen many customers start with just a couple of integrations and quickly expand to more because they realize how much time and effort they were wasting.

Manual Data Entry: The Biggest Hidden Cost

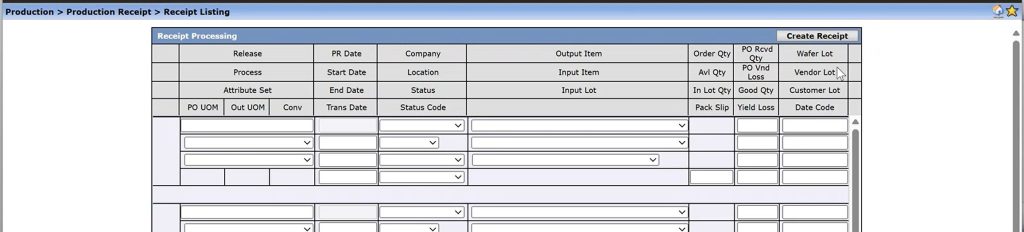

When wafer tracking is done manually, users must enter every detail themselves, sometimes 12 or more entries for a single production release. Suppliers send paypoints when the actual inventory movement is being made, WIP updates, and schedules, and all of this must be typed into the system manually if spreadsheets are involved.

This manual work adds up to significant labor cost, and it introduces risk. The accuracy of the entered data depends entirely on the user.

With integrations, suppliers send structured files that automatically populate receipt listing fields. About 95% of the work is done instantly, and users only need to review and submit. No repetitive data entry, no delays, and no manual errors.

WIP Tracking: Daily Work You Shouldn’t Be Doing Manually

WIP files arrive daily and give you an idea of where your inventory is at a given moment. Without automation, users have to maintain schedules themselves like creating new records, filling out fields, and updating statuses manually.

With integrations, this data flows automatically into the system. Teams can instantly view quantities, commit dates, shipment details, and statuses without touching a spreadsheet. Even if minor adjustments are needed, it’s far more efficient than recreating everything manually.

The hidden cost isn’t just time, it’s the constant attention required to keep spreadsheets up to date.

Invoicing Without Integrations = More Manual Work

After receipts are processed, invoices must be created. Without integrations, that’s another round of manual data entry.

With automated invoice integration, suppliers send invoice files that match receipts already in the system. Invoices appear automatically, eliminating yet another repetitive task.

The Real Problem With Spreadsheets

When companies rely on spreadsheets, the entire process is in the hands of individual users. That means more errors, more delays and more time spent doing work the system could handle automatically.

Integrations streamline everything from receipts to WIP to invoices and remove the need for constant manual oversight.

How Tensoft SemiOps Helps

Tensoft SemiOps replaces spreadsheet‑driven processes with fully integrated workflows that automate receipt creation, WIP updates, and invoice matching. Suppliers send data directly into the system, eliminating the need for users to manually create schedules, enter receipt fields, or create invoices by hand. By streamlining these workflows end‑to‑end, SemiOps reduces labor costs, accelerates processing, and gives teams accurate, real‑time visibility into what they have in the system and where it is without the hidden operational costs that come with spreadsheets.

To learn more about Tensoft SemiOps, visit our website or contact us today!