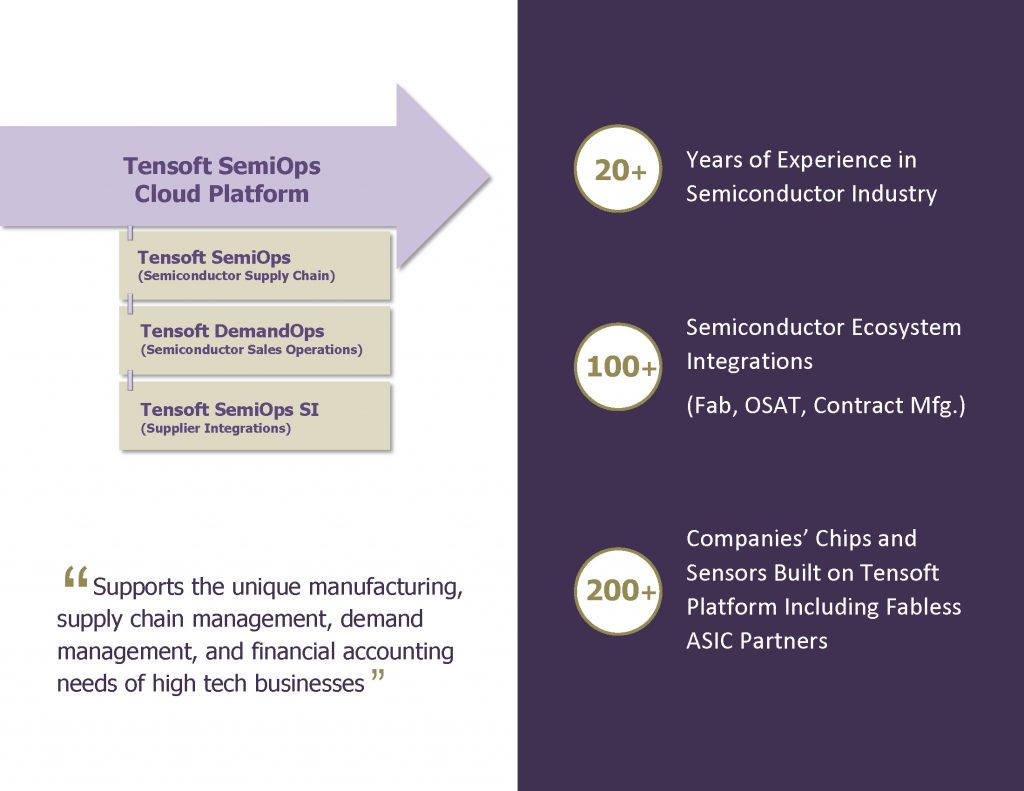

Our fabless semiconductor management solution – Tensoft SemiOps – has been purpose-built for the semiconductor industry, which is why we’ve amassed a long list of semiconductor customers over the years. We’ve seen how Tensoft SemiOps has benefited these customers by providing out-of-the-box functionality that can be deployed quickly; functionality that’s not available out-of-the-box anywhere else.

Here is just a sample of some of the industry-specific functionality in Tensoft SemiOps:

Manufacturing Operations: Tensoft SemiOps supports the flow/lot-based production model, as well as the supplier management for an outsourced supply chain. The flow tracking process produces product metrics (yield, cycle time, WIP status), the outsourced production procurement management (including consigned inventory, and build instructions), and the reporting. This would take multiple spreadsheets and manual processes to maintain in a standard ERP.

Supplier Integration: In Tensoft SemiOps, you can easily add the supplier integrations when needed. It integrates the supplier’s WIP and Pay Point outputs to your system (with options to add supplier invoicing) – eliminating manual effort as well as adding depth to the information you have to manage your suppliers.

Inventory Genealogy and Traceability: The integration of product configuration and build instructions with production results and inventory movements (including shipping) results in a complete map of your production. The detailed genealogy (including all data collected for every step of the production process) and the ability to trace inventory and customer shipments is very challenging to do manually and is very helpful for outside audit support.

Inventory Valuation and Costing: The semiconductor industry runs on standard cost using a process accounting costing model – the outputs from the production process are significant influencers for how inventory is valued. Yield, rework, multiple process flows to get the same product result, and production / procurement cost variability (including lot charges) all impact inventory value and variance. There is really no easy way to build this inventory costing into a standard ERP system – since the inputs to the production process are the Manufacturing Operations results. In SemiOps, your production cost analysis and inventory value change are results of your manufacturing process.

Sales Order Management: If you sell to distributors you have additional needs in your order management process. If you sell through an extended value change – where your end customer is not your sell to customer you have additional needs as well. Beyond this the need to track change, the need to support multiple part numbering and pricing models, the need for request and commit date management, and outsourced fulfillment all drive requirements that are standard in SemiOps, but are hard to achieve in standard systems.

Other Financial Impacts: include standard cost change management and cost roll-down support based on the product flow models, and invoice matching for supplier invoices. For the invoices – it isn’t usually something people think about – but there are quickly lots of invoices from suppliers, and the suppliers are better at identifying the lots they are invoicing (and not very good at identifying purchase orders and receipts). We let you match invoices at the lot level. Often, we save people $40K or more in supplier costs (due to payment of invoices that aren’t needed) in the first year plus.

To learn more about Tensoft SemiOps, view this fact sheet or contact us.